UV Pulsed Light and air cooling

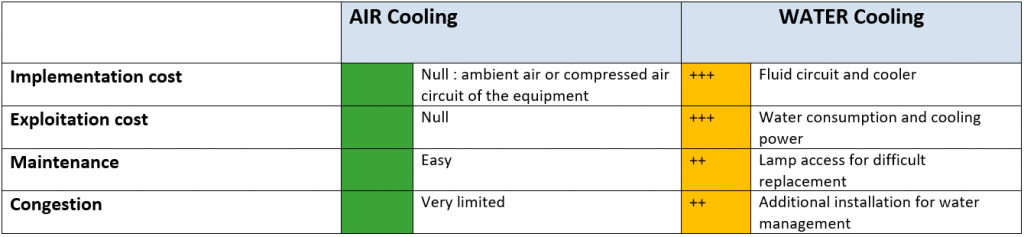

The air cooling of the Pulsed Light modules significantly reduces purchasing and operating costs while guaranteeing perfect efficiency for firing frequencies of below 1 Hz.

Cooling UV pulsed light modules is a major challenge. It influences decontamination performance and integration constraints on industrial systems for processing jars or other packagings.

UV Pulsed Light technology involves emitting a large amount of electrical energy in a lamp which then converts it into light energy. This high power light emission induces heat build-up of the lamp and more precisely of the contacts, the electrodes and the quartz enveloppe.

It is therefore necessary to implement a cooling system to ensure that the lamp life objectives are met as well as the reproducibility of the characteristics in light emission.

Manufacturers of UV pulsed light modules generally offer a water cooling system. This is not the case with Phoxene, which implements a compact, low cost and easy to maintain air cooling system into its solutions.